Industrial Equipment Simulators

Using interactive 3D

Virtual Reality & Augmented Reality

Step by step interactive simulators for the installation, operation, maintenance and troubleshooting of YOUR equipment.

Free Quote

Our education & training solutions, our online interactive 3D simulators, train and certify more operators, installers, and maintenance personnel faster and better, yielding higher-performing and safer trainees.

Boost operator knowledge management. Capture best practices. Accurately reflect site-specific and equipment-specific processes. Significantly reduce operator errors and risk.

Speed up training efficiency and effectiveness. Decrease upfront training costs for new personnel adding extended personalized practice sessions.

Up-to-date multi-device mobile 3D manuals improve Environment, Health & Safety (EH&S) compliance for safer shutdowns, turnarounds, lower emissions, and more.

Minimize on-site training and associated costs including travel, accommodation, supervision.

Extremely realistic interactive 3D virtual versions look, feel, sound and work exactly like the real thing... at any scale.

Our multilingual team of project managers and simulation designers interface with you in fluent English, Spanish, French, German, Russian, Dutch or Afrikaans. Interfacing in other languages available on request.

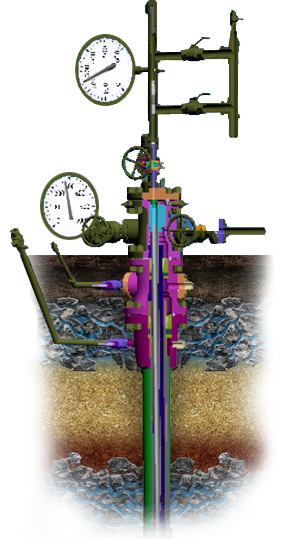

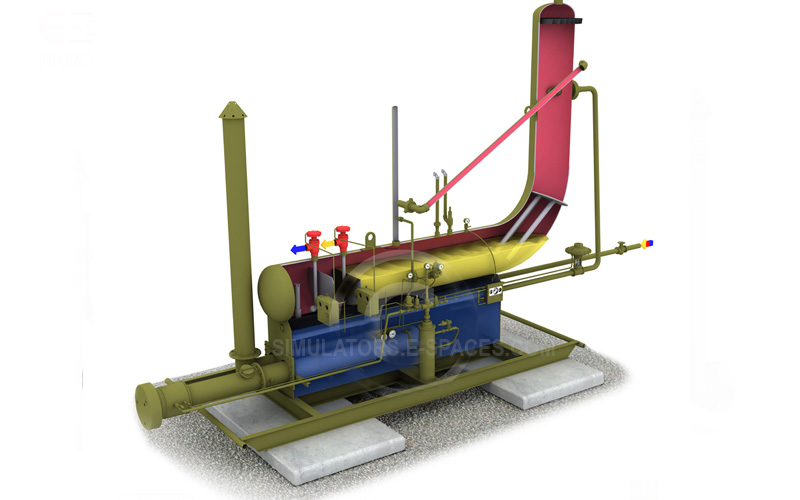

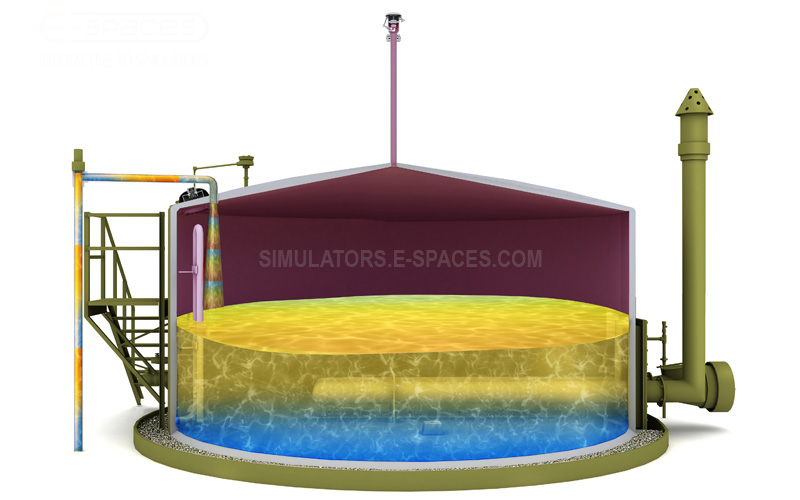

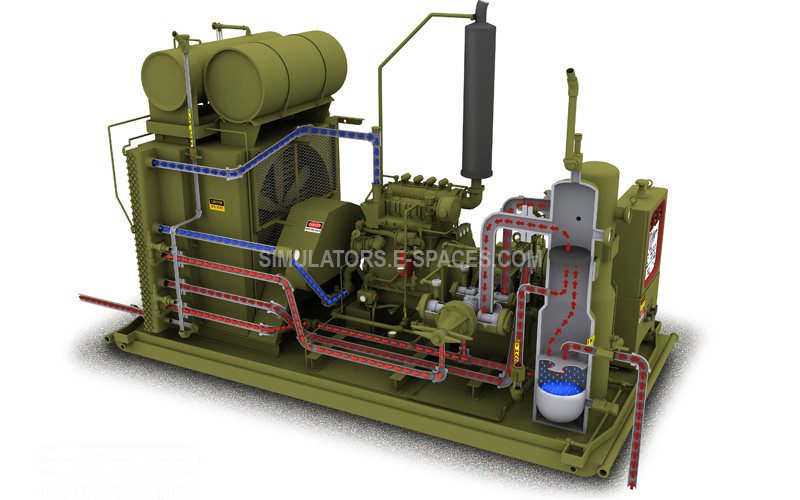

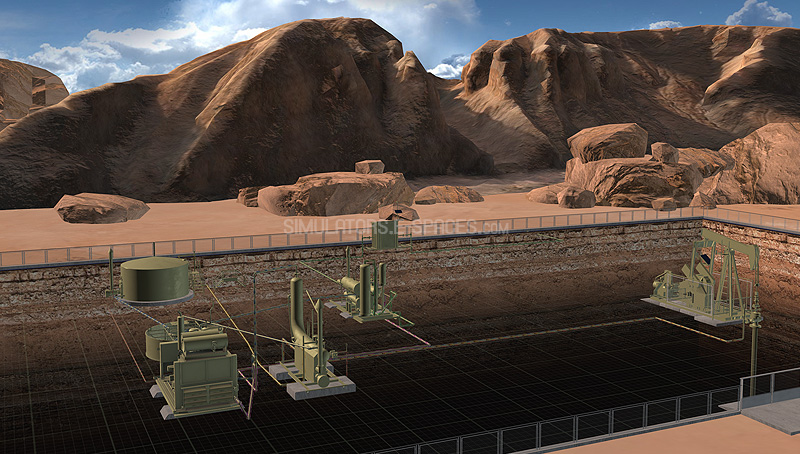

Interactive 3D VR/AR training simulators we produced so far include all the surface equipment of well locations including a heater-treater, wellhead Xmas tree, pumping unit, compression unit, L-PUD, 1-stage separator, dehydrator, tank, meter runs, plunger lift and more. These were produced to train and certify lease operators in the oil & gas industry. The simulators faithfully reproduce the internal and external working of existing equipment including start-up & shut-down procedures, assembly & disassembly, maintenance & troubleshooting procedures and more.

INTERACTIVE — NATURAL — INTUITIVE

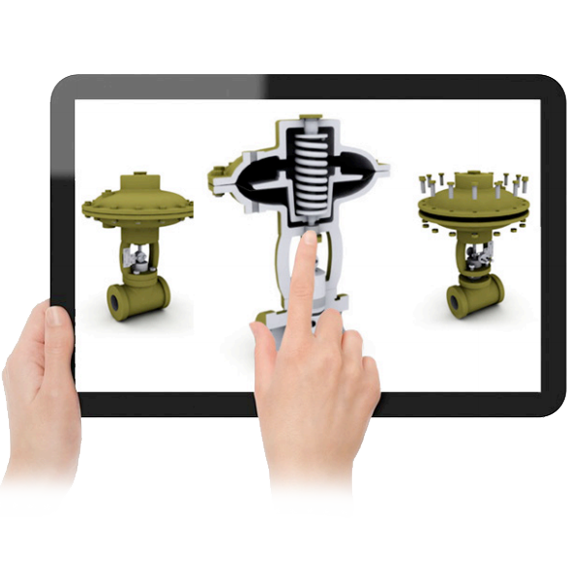

Interactive 3D real-time training simulators and manuals are ideally suited to the technical training of the operation of highly complex industrial equipment. Simulators allow students to literally see, hear, feel and interactively understand the inner workings of machines, systems and even entire installations such as refineries and power plants. They can interactively examine and explore them from all sides as well as in fully animated interactive 3D cut views.

Interactive augmented reality and virtual reality technology allows the playing out of different security and safety related simulations without putting the students into any kind of danger. We can program step by step solutions for every standard problem.

For predictive maintenance projects we read key data using sensors, create a real-time updated virtual model of the system, run diagnostics, notify personnel about a problem if the sensor data goes outside of parameters. Using augmented reality, the operator can quickly identify the location of the problem and attempt a fix with real time feedback. This solution greatly reduces human errors and can prevent ecological disasters.

Got questions? We’ve got answers. If you have any other questions, feel free to send us an email to info@e-spaces.com

If you have to train personnel to operate complex equipment, we can empower you by turning this into easily navigable, intuitive interactive lessons… delivered to any web-browser on any device. The simulator loads and your trainees can explore the highly interactive and visually rich explanations using VCR style controls.

If you have Autocad files or a 3D model of the machinery you would like to train people on, that would be an ideal starting point. If you don’t have such, we will need to photograph the equipment in order to create a 3D model. Next, we need a step by step description of the process(es) to be trained. Multilingual narration can be added if needed. These answers apply to strictly software-based 3D simulators. Preventive maintenance involving augmented reality may also require hardware to interface with. Production of such may take longer than a strictly software-based approach.

For surface equipment, it can take from one to three months, depending on the materials you provide us and the complexity of the equipment, the number of steps to be trained, as well as a few additional parameters. It can take longer if you need to train safety procedures involving people / workers / operators.

The simulators work in any browser on smartphones as well as on tablets.